Turret Punch Press Machine

Turret Punch Press Machine

Turret Punch Press Machine

New Generation Turret Punch Press

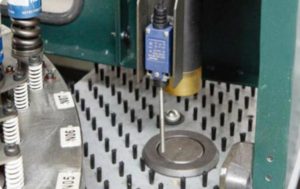

Our CNC turret punch press machine is the flexible automated punching by hovering feature to mark the next tool on the exact location to be punched in materials as programmed without manual set-up & delay. It involves pushing a press die in the metal sheet to create as many varieties of shapes with different diameters upon your fabrication requirements. It uses low energy, high efficiency of turret press, low maintenance cost, support of wide turret plates with every die and punch ensure less service, increases lifespan and minimizes tool deflection. We adopt a brush and ball worktable to facilitate easy processing, high resistance to movement, protect the metal plate from scratches very well and make the loading & unloading process easy.

Model: SMART-SF-20 / SMART-SF-30

Functions & Features

- The turret punch press machine manages the tool and sheet repositioning automatically according to the given programming procedure without losing the same level of resistance and degree of rotation. The automatic possibility of rotating between tools allows reducing the number of tools to be purchased individually and time to place manually.

- It can insert multiple independent punches in a single station and takes a second to change the tool within the clever designed multi-tool section. It adopts an integrated cast thick turret structure that increases the capability, flexibility, productivity and speed of the punching machine.

- FANUC CNC Controller provides you realistic operating, designed to support the machining needs precisely, reliable machine control capable of handling the complex machining processes and used to track the programmed tasks.

- Sheet jam protectors are used to detect the warped, deformed, or buckled sheets and the machine stops automatically when triggered.

Technical Specification

| Item / Model | SMART-SF-20T | SMART-SF-30T |

|---|---|---|

| Nominal Force | 200 kN | 300 kN |

| Max. Sheet Thickness | 4 mm | 6 mm |

| Max. Tool Size | Ø 88.9 mm | Ø 88.9 mm |

| Max. Sheet Size | 1250 X 5000 mm | 1250 X 5000 mm |

| Punching Accuracy | ± 0.1 mm | ± 0.1 mm |

| Driving System: Drive Type | Servo V.R. | Servo V.R. |

| Driving System: Ac Motor Power | 16 kW | 16 kW |

| Max. Sheet Weight | 100kg | 100kg |

| Max. Marking Rate | 1800 h.p.m | 1800 h.p.m |

| Max. Punching Rate (10 mm stroke): 1mm Pitch | 1000 h.p.m | 1000 h.p.m |

| Max. Punching Rate (10 mm stroke): 25 mm Pitch | 500 | 500 |

| Max. Feed Rate | 110 m/min | 110 m/min |

| Quantity of Rotary Station | 32 (2) | 32 (2) |

| Rotary Station: Exchangeable Tool Type | C/D/MT6A/E | --- |

| Rotary Station: Quantity of Secondary Indexing Sub Tools | 12 | --- |

| Quantity of Control Shaft | 6+1(X / Y1 / Y2 / T / C / C1 / A) pcs | 5 (X / Y / T / C / A) pcs |

| Machine Weight | 16000 kg | 16000 kg |

| Machine Dimension (LXWXH) | 4965 X 5200 X 2110 mm | 5940 X 5200 X 2420 mm |

Components Details & Other Information

Clamp

The turret punch press machine has automatic clamp positioning capable of accurate positioning and rapid clamping. It reduces errors, setup time and enhances the machine run-time, flexibility and productivity.

Solid Frame Structure

Solid frame structure provides high strength, high rigidity improves the lifetime of the machine, protects from deformation to ensure the proper processing of materials.

Servo Drive Motor

It uses the servo motor with high torque to drive the gearbox that provides high power and speed. This allows the motor to adjust the punch stroke position and achieve the complex curve requirements.

CAD/CAM Nesting Software

By using the nesting software, can able to nest multiple parts. It maximizes the sheet utilization with less waste, ensures workflow, optimum performance and allows the sheet metals to process easily.